Offshore-Gratings

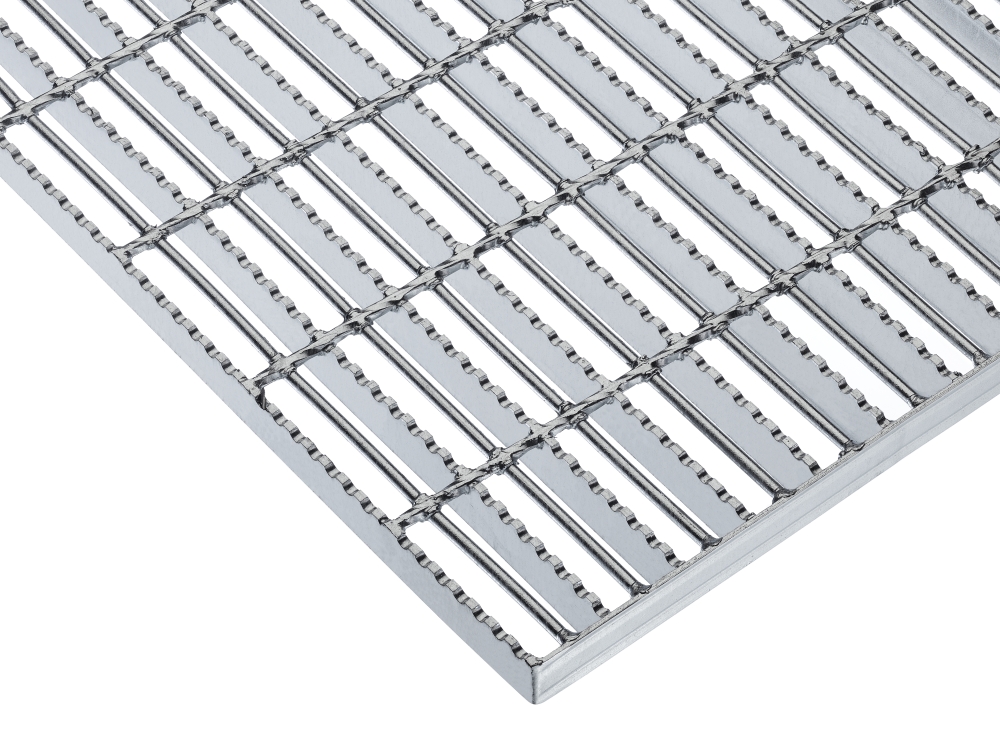

Lichtgitter offshore gratings have been specially developed for use on offshore platforms.

In addition, round bars welded in the bearing bar direction reduces the given bearing bar pitch so as the falling through of a test ball having a diameter of 15 mm is prevented.

Characteristics

- Absorption of high horizontal forces by pressing and welding of all intersection points

- Due to the additional round bars welded in the bearing bar a 20 mm or 15 mm ballproof can be reached

- High resistance

- High bearing capacity, because bearing bars are not weakened by welding of cross bars

- Good torsional rigidity even with subsequently introduced cut-outs - maintenance of the homogeneous unit

All characteistics can be combined. Please contact us to check the producibility of the gratings. Our sales department is always at your disposal.

Our Offsjore-gratings meet the requirements for serration class R12.

| Bearing bar pitch | Cross bar pitch | |

|---|---|---|

| 34,33 mm | 101,60 mm | |

| 41,46 mm |

| Bearing bar thickness | Bearing bar height | |

|---|---|---|

| 3 mm | 25 mm | |

| 5 mm | 30 mm | |

| 35 mm | ||

| 40 mm | ||

| 45 mm | ||

| 50 mm |

Types of Offshore-gratings

| SPOX13 530-41/101-5 | |

|---|---|

| SP | Forge-welded graints |

| O | Offshore |

| X13 | Serration No.13 |

| 530 | Bearing bar 30 x 5 mm |

| 41/101 | Pitch: 41,46 x 101,6 mm |

| 5 | Banding: 30 x 5 mm |