Home | Produkte | Gratings | Forge-welded gratings | Offshore grating

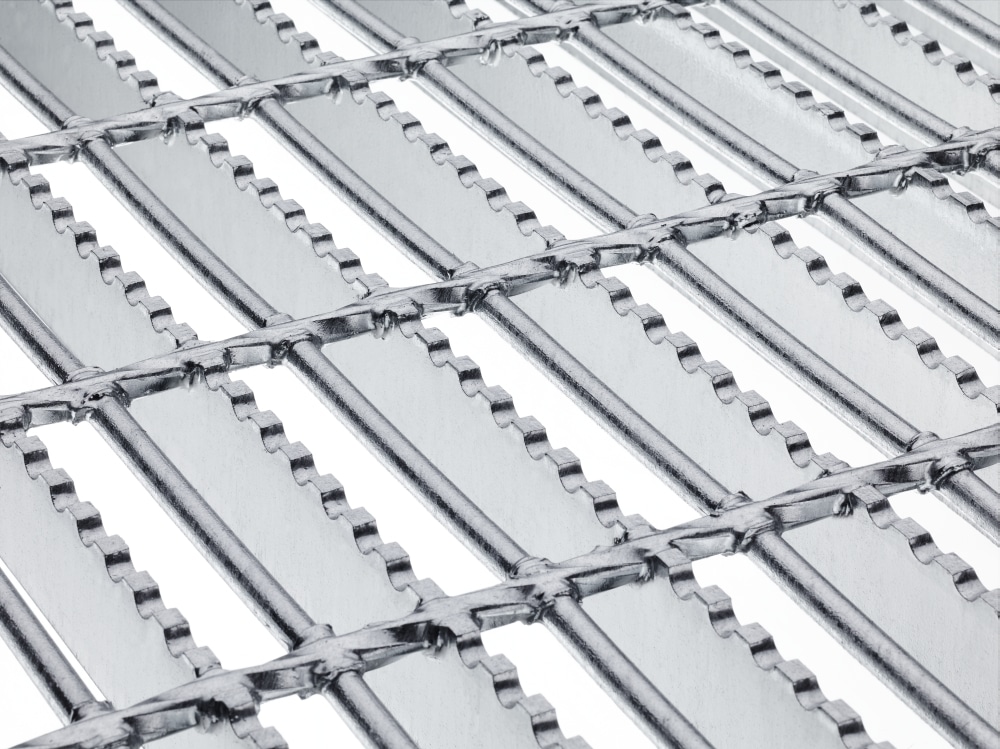

A 20 mm or 15 mm ball proof can be achieved thanks to the round wire welded underneath

High resistance

High bearing capacity, as bearing bars are not weakened by welding in cross bars

Good torsional rigidity even with subsequently installed cut-outs

Lichtgitter offshore gratings achieve a ball proof of 20 mm thanks to the additionally welded-in round wire – or even 15 mm for particularly safety-relevant areas. Offshore gratings belong to the so-called special gratings and are available from a quantity of 300m².

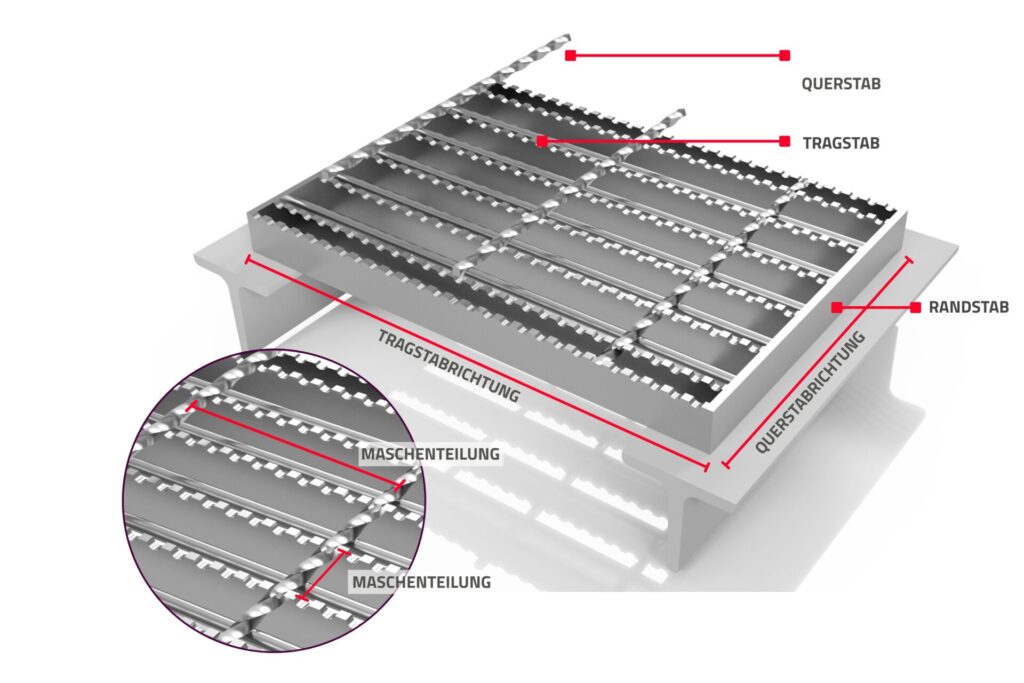

Type: SPOX13 530-41/101-5

SP |

forge-welded grating |

O |

Offshore |

X13 |

Slip resistance no. 13 |

530 |

Bearing bars 30 x 5 mm |

41/101 |

Pitch: 41.46 x 101.6 mm |

5 |

Banding: 30 x 5 mm |

Discover our fastening systems.

Gratings Tailor-Made. We supply you with pressed and forge-welded gratings in the common standard types in 6-8 working days and in max. 10 working days including technical processing.

We have an extensive stock program. This means you can receive gratings, grating steps, perforated metal planks and GRP-Products in common standard designs and dimensions within 48 hours.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information